The useful life of an electrical machine is commonly associated with the service life of the insulation material, especially in large machines, as we have covered in previous articles.

The failure of the insulator is usually the result of a gradual deterioration, over time, which we call aging. Aging is basically the result of different stresses: thermal; thermo-mechanical; mechanical; electrical; and environmental, which act simultaneously in operation. The insulating system can change its behavior as a function of the various types of “over stresses” when compared with the behavior of normal aging.

The insulation system in large machines is one of the most important parts because of the high manufacturing and maintenance costs. Around 40% of the failures in large machines are due to the high-voltage insulating systems, according to research.

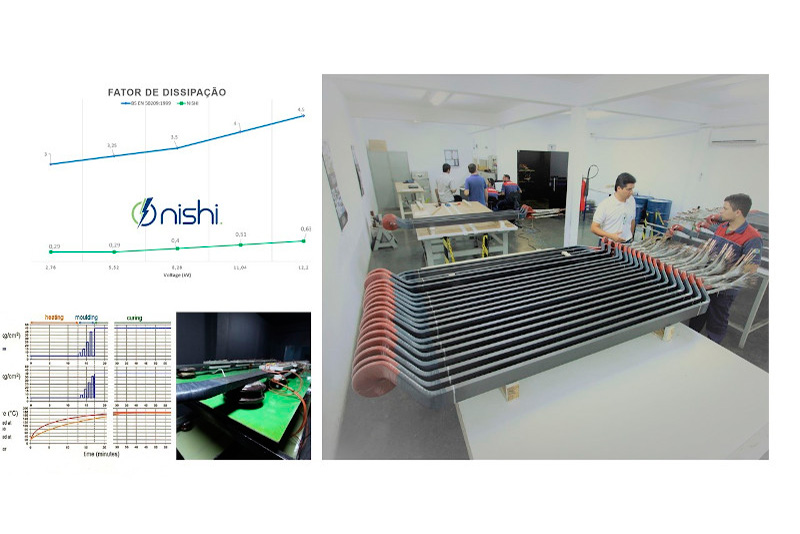

The study of the behavior of insulating material subjected to different stresses during its operation is very important to improve the design/process and the quality of the insulating system and thus avoid early aging.

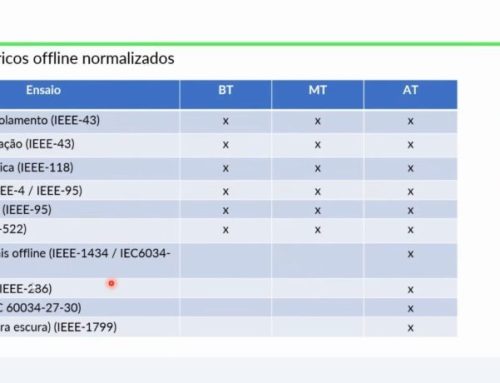

One of the most common tests for approval in coil manufacturing is the VET – “Voltage Endurance Test”, according to IEEE 1043 (test method) and IEEE 1553 (acceptance criteria). This test simulates an accelerated aging through thermal and electrical stress simultaneously, in a test room, with 4 (four) prototype coils. Only after its approval the process is approved and released for coil manufacturing.

Contact our team and get to know the techniques to evaluate the insulation system and which is the best coil manufacturing project/process for your equipment.