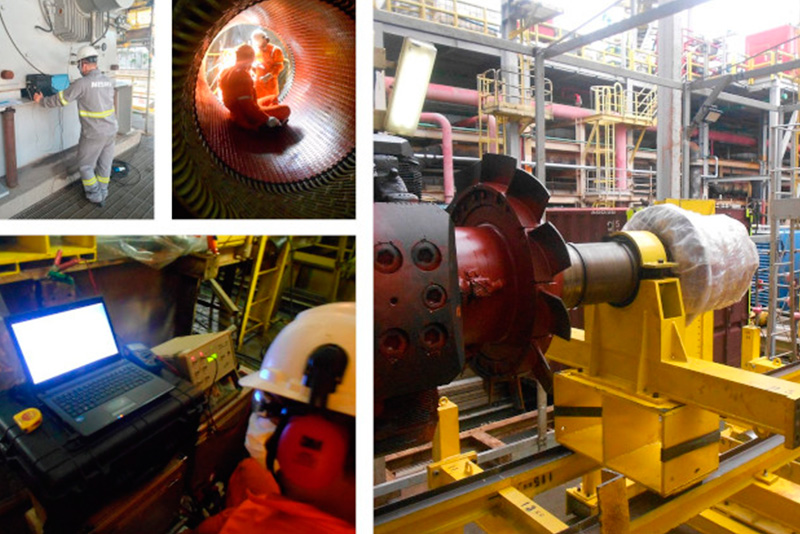

Predictive maintenance consists of periodically monitoring the condition of equipment, providing information from the analysis of collected data.

Through this monitoring, the maintenance management may be able to foresee possible failures and malfunctions, reducing the probability of performing corrective maintenance. Consequently, optimizing the operational availability of the equipment, increasing productivity and reducing the cost of operation.

It is noteworthy that the performance of predictive maintenance does not exclude the need for preventive and corrective maintenance. Thus, it aims to reduce the number of unexpected failures and provide complementary information for preventive maintenance.

Thus, the main benefits of a maintenance management that uses predictive maintenance in its programming are:

- Reduction of maintenance costs;

- Increase in the mean time between failures;

- Reduced machine repair time;

- Increased productivity, availability and reliability of the machine;

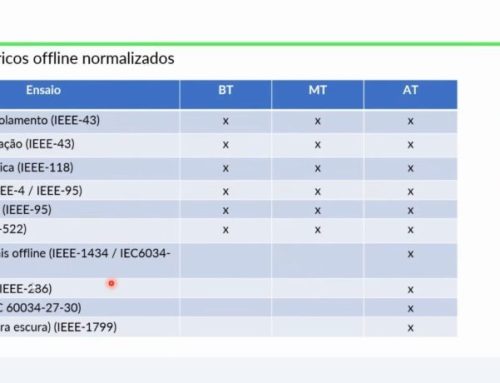

Read more Nishisan tips in our BLOG and access the content of a lecture held by NISHI about the Effectiveness of Predictive Analysis: Expertise + Technology. Contact our team and evaluate your maintenance strategies with information and data collected.