What is the expected operating time for an electric motor? 10, 20, 30 years?

A common first question is what determines motor life? Is it determined by the lifetime of the insulation material? By the wear period of the bearings? By the deterioration of the steel? Others?

When we “explode” a motor and stratify its components we see in its composition basically steel, copper and insulating materials. When comparing the materials, we conclude that the insulating material is the most fragile in relation to the others. Is it correct to say that the life span of the motor is determined by the life span of the insulating material? What about the bearings that wear out over time, is it correct to say that the end of their life is the end of the motor’s life?

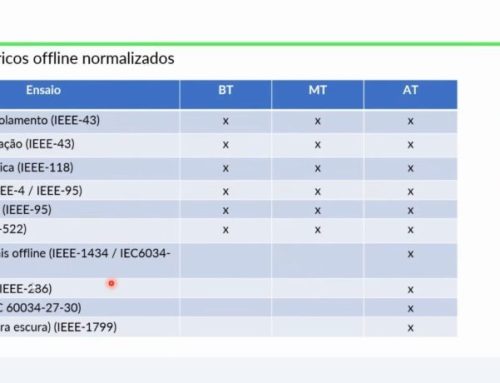

With good maintenance practices, ensuring the integrity of the insulation system can be a determining factor for long motor life. In medium and high voltage motors, predictive and preventive maintenance will prevent the acceleration of the aging of the insulation system. Statistics show that the stator winding alone accounts for almost 40% of failures.

Having knowledge of the failure mechanisms of a motor’s insulation system and intervening in them will ensure long-lasting uptime. We list below the main causes of failure or accelerated aging:

- high motor temperature;

- electrical stress;

- high contaminant environment.

It is common for all three phenomena to act simultaneously.

Learn more about the services provided by Nishi and contact one of our experts for information about failure modes of insulation systems.