Turbo-Generators

NISHI specializes in the maintenance of alternating current generators with smooth and salient pole rotor of all sizes used for industrial applications and electrical generation. They are driven by steam turbine, gas turbine or combustion engines.

Operation and maintenance of the generator must be in accordance with the manufacturer’s instructions and within the prescribed mechanical, thermal, and electrical limits. Condition monitoring and predictive maintenance strategies can be used to define disassembly and inspection intervals.

Most turbogenerators undergo two types of dismantling: a major (long, complete) dismantling and a minor (short, partial) dismantling. A major (complete) dismantling usually involves the removal of the generator rotor. During a minor (partial) disassembly only the access covers are removed.

Visual Inspection:

Visual inspection by a generator specialist is a highly effective method of detecting problems with the generator. Perform visual inspections at every disassembly and at every other opportunity. Operation and maintenance in accordance with manufacturers’ instructions will prevent losses, but further recommendations should be observed based on the following factors:

- Operating history;

- Machine availability

- Electrical test results

- Results of condition monitoring

- Failure history;

- Equipment alerts;

- Maintenance history;

- Previous disassembly report;

- Exposure to severe or abnormal operating conditions;

- The most common failure modes in AC generators are related to the stator, core, and rotor.

Os modos de falhas mais comuns nos geradores de corrente alternada estão relacionados ao estator, núcleo e rotor.

STATOR

Stator winding failures occur when the insulating wall or inter-spiral insulation fails and allows a short circuit to occur.

Thermal deterioration failures occur when the generator is operated at temperatures above the thermal rating of the stator winding insulation. Problems in the insulation cause delamination of the mica tape layers of the insulation. There will be friction between the loose conductors that damage the insulation, resulting in electrical short circuits. Delamination of the mica tape layers also creates gaps in the insulation, where partial discharge activity can occur, and eventually erode a cavity in the insulation causing an electrical short circuit.

Causes of thermal deterioration include:

- Generator overload;

- Poor design or manufacturing;

- Poor thermal exchange caused by high ambient temperatures, blocked air filters, clogged heat exchanger tubes, and blockage of generator cooling passages and vents;

- Overexcited and underexcited operation of the generator continuously;

- Negative sequence currents caused by phase imbalance of the stator currents;

- High harmonics in the electrical system contributing to increased heating in the stator and core.

• Partial Discharge

The activity of partial discharges in the insulation tends to contribute to the evolution of voids present in the insulation. Over time, they can create enough stress to weaken the winding until a possible short circuit occurs

• Corona

The corona effect is a type of partial discharge that occurs at the stator endwinding, slot exit, and especially between phase coils.

• Duty Cycle

The load cycle causes insulation failure as a result of the difference in thermal expansion between the stator copper conductor and the insulating wall. The copper expands faster than the insulating wall and will result in an axial shear stress between the insulation of the insulating wall and the copper conductor. With repetitive load cycles, the copper will eventually separate from the grounding wall insulation. The gap created will allow partial discharge to occur. The gap also allows the copper conductors in the bar to loosen and vibrate, leading to insulation damage.

• Loose stator bars

Loose stator bars will vibrate radially in the groove. This causes the insulation to be worn away from the surface of the groove. The movement of the stator bar in the slot also generates discharge in the slot which, over time, becomes partial discharge as the semiconductor layer on the stator bar is worn away. The partial discharge will accelerate the deterioration of the insulation.

• Defective semiconductor coating

Stator bars in machines rated 6 kV and above are usually coated with paint or tape that use carbon raw material to give the coating a semiconductor property. However, oxidation of the carbon raw material can occur due to partial discharge activity or localized areas of high resistance in the coating. This will reduce the effectiveness of the semiconductor coating and allow more partial discharge activity to occur, eventually leading to insulation failure.

• Overvoltages

Overvoltages due to lightning, electrical faults, and switching will cause the insulation to fail if it is stressed beyond its ability to withstand.

• Contamination

Open air-cooled AC generators usually operate in environments where they are exposed to contaminants such as dust, salt spray, moisture, and chemicals. These open generators are susceptible to arcing, erosion, and chemical attack as a result of these contaminants.

• Core

The stator core is made of steel laminations. These laminations are insulated from each other to reduce the amount of eddy currents that are induced in the core. Eddy currents generate heat and losses in the generator. Deterioration of the interlaminar insulation will result in overheating and damage to the core. The damage can be severe and can result in damage to the windings.

ROTOR

Rotor insulation consists of two components: (1) insulation between the pole winding and the pole body, and (2) inter-wire insulation, which provides individual insulation between the windings of the rotor winding for each pole.

Pole insulation for small and large generators is generally the same. In modern machines, this consists of insulating glass laminate between the winding and the pole shoe that ensures the necessary dielectric and mechanical strength.

Insulation of the winding in smaller generators consists of enamel and fiberglass insulation of the conductor. In larger generators, spiral insulation consists of a separator of insulating material placed between each flat copper strip or tape of insulating material wrapped around the copper strips.

• Faulty connections between poles

Each pole in a salient pole rotor is connected in series by screwed or abraded interpolar connections. During operation, the rotor poles will move relative to each other, causing the interpolar connections to rub together. Over time mechanical fatigue can cause the interpolar connections to break, resulting in an open-field winding. It can occur even with flexible laminated interpolar connections.

• Rotor insulation failure

Rotor winding failures can also occur when the pole or spiral insulation fails and allows a short circuit to occur. It is possible for the generator to continue operating with shorted rotor windings. Shorted turns also result in increased vibration due to the asymmetric magnetic field.

Turbogenerators Cases

FREE WEBINAR: Generator failure – Root Cause Analysis (RCA) of 2 generators with insulation breakdown

Nishi and Quartzelec would like to invite you to attend the on-line meeting where we will be discussing: Generator failure - Root Cause Analysis (RCA) of 2 generators with insulation breakdown. We will be discussing

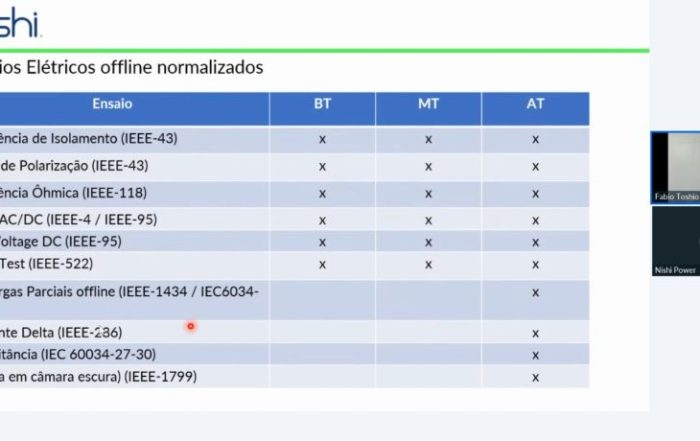

Electrical Tests: Low Voltage Winding x Medium High Voltage

Nishi-san's tips on medium and high voltage motor and generator maintenance are back, now with live broadcasts and open participant Q&A. Watch and participate in this online event with lots of technical content and the

BRUSHLESS EXCITATION SYSTEM ON GENERATORS

How does the brushless excitation system work on generators? The brushless excitation system consists of an AC exciter and a rotary rectifier mounted on the same shaft as the generator. The exciter resembles a commutator

Would you like to receive exclusive content about electrical machines?

Nishi has specialized in repairing and maintaining your equipment for over 70 years.

Register your e-mail and receive all the news in the sector.