For the electric machines, preventive maintenance is a common practice and the market commonly uses the word rejuvenation when requesting this service, which can give a wrong connotation when looked at literally

Rejuvenation: act or effect of rejuvenating, of making younger…

In maintenance we have no way to make the machine “younger”. An insulating system, a bearing system, or others do not become younger after an intervention of this nature. Only in complete corrective maintenance can we rejuvenate it. By replacing the coils, the bearings and other items with new ones, we will be restoring the useful life of these components.

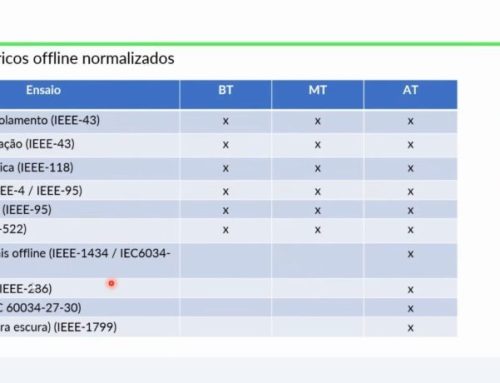

We consider preventive maintenance, which we prefer to call Overhaul (act or effect of reviewing or revising; inspection to correct or prevent failures). With the improvement of predictive techniques is increasingly common to preventive intervention as a complement to the indications and trends evaluated in predictive intervention.

In this work, the “keen eye” of the technical expert is fundamental to see, inspect, test, and systemically evaluate the components. To detect potential loss of life and also intervene at points that may be accelerating the aging process.

Inspections of the cooling system, insulation system, winding tie system, corona and partial discharges, wedges, bearings have avoided early and unexpected losses when detected and corrected. However, as we said, there is no way to “rejuvenate” if they are already aged.

Read more about the GAP-N electrical predictive analysis methodology for rotating electrical machines by clicking on the link: