Large generators operate with a high current density due to their high power. Under these conditions, and due to electrical principles, “Foucault” and circulating currents occur, phenomena that arise when conductors are subjected to intense magnetic fields. As a consequence of these effects, we can have high winding losses and heating.

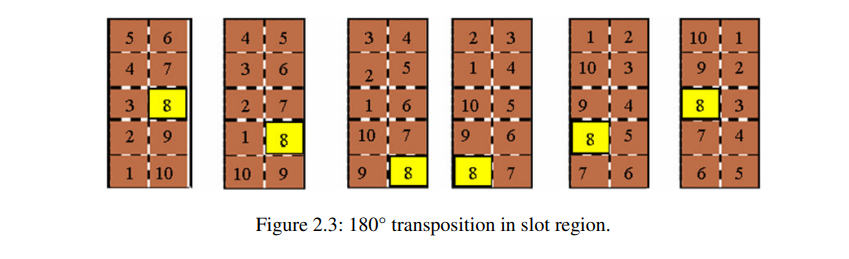

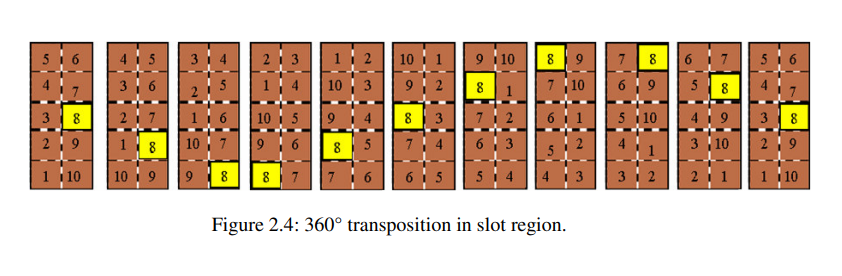

To ensure the loss levels and yields of these machines, the generators are designed with coils formed by multiple rectangular conductors in parallel, insulated from each other (“strands”) and transposed along their length, which we call “Roebel” transposition. Each parallel conductor is designed with a small cross section because in this way the eddy currents are reduced (Fujita, Kabata – 2005).

The commonly used transpositions are 360º and 180º. Studies show that in the 360º transposition the losses by circulating current reach close to zero.

Access our blog and read more NISHISAN tips on corrective maintenance services and characteristics of electrical machines. Contact our team and ask all your questions about different coil and bar manufacturing projects for turbogenerators and hydrogenerators.